Services

OUR SERVICES

We offer a full range of Advanced Non-Destructive Testing (ANDT) services to ensure the safety and reliability of your assets. Our certified experts use cutting-edge techniques to detect defects without damaging your components. Serving industries like oil & gas, power, aerospace, manufacturing, and construction, we deliver inspections tailored to the highest quality and safety standards.

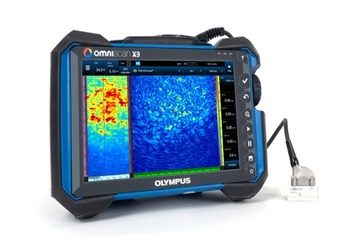

PHASED ARRAY ULTRASONIC TESTING (PAUT)

PHASED ARRAY ULTRASONIC TESTING (PAUT) technique are being employed in various applications during manufacturing process or onshore and offshore in-service

Read More

TIME OF FLIGHT DIFFRACTION (TOFD)

TOFD Advanced Ultrasonic Testing techniques are mainly used during manufacturing process or in-service for butt weld inspection on Pressure vessel, Piping, Storage Tanks

Read More

FULL MATRIX CAPTURE PHASED ARRAY(FMC/TFM)

Full matrix capture (FMC) & Total focusing method (TFM) is a new technique of phased array (PAUT) as per 2019 edition of ASME code. FMC is data acquisition technique

Read More

MANUAL ULTRASONIC TESTING (MUT)

Manual Ultrasonic Testing (MUT), since its an affordable solution for every customer so its first choice in all sectors in various application.

Read More

MAGNETIC PARTICLE TESTING (MPT)

Magnetic Particle Testing (MPT) is a powerful non-destructive testing (NDT) method used to detect surface and near-surface defects in ferromagnetic materials.

Read More

LIQUID PENETRANT TESTING (LPT)

Liquid Penetrant Testing (LPT) is a widely used non-destructive testing (NDT) method designed to detect surface-breaking defects in non-porous materials.

Read More

UT THICKNESS TESTING

Ultrasonic Thickness Testing (UTT) is a widely used non-destructive testing (NDT) method that measures the wall thickness of materials from one accessible side. It is especially effective for detecting corrosion, erosion, and material loss in pipes, tanks, pressure vessels, and structural components.

Read More

HARDNESS TESTING

Hardness Testing is a key Non-Destructive Testing (NDT) method used to determine a material’s resistance to deformation, wear, and indentation. It plays a vital role in quality control, heat treatment verification, and material selection across various industries.

Read More